What is Bearing Steel? Details

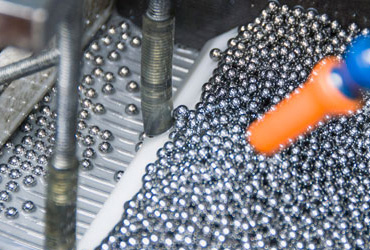

What is Bearing Steel?

What is Bearing Steel?Bearing steel is a deep hardening alloy used in aircraft bearings or other highly stressed components requiring good rolling contact fatigue strength at temperatures below 400 degrees. The 52100 vacuum melted steel material offers superior cleanliness and internal stability compared to conventional air melted SAE 52100.

Bearing ball steel is a through hardened chrome alloy steel used in rolling contact and other high fatigue applications. In the hardened state, high hardness, strength and cleanliness provide the steel with the correct properties to withstand high cycle, high stress fatigue. 52100 is mainly used for small and medium bearing components. It is also frequently used in other machine parts that require high tensile strength and high hardness.

52100 round steel bearing steel is a special steel with high wear resistance and rolling fatigue strength. High-carbon chromium bearing steel, engineering steel and some stainless steel and heat-resistant steel are used as bearing materials and other purposes.

Features of Bearing Steel

* Excellent hardness, Rockwell (Rc) 60-67 at room temperature

* High Carbon Chromium Alloy Steel

* Continuous operation at temperatures up to 120°C

* For the production of precision ball and roller bearings

* Cost-effective

* Long lasting

Applications of Bearing Steel

Alloy steel 52100 grade bearing steel is mainly used in the manufacture of high stress parts such as aircraft bearings. This steel grade 52100 steel is best vacuum arc remelted to provide optimum properties. Typical applications: bearing manufacturing, constant velocity joints, ball screws, gauges, cutting tools, etc.

Comparable Standards:

| AISI/SAE | DIN | JIS | GB |

| 52100 | 100Cr6 | SUJ2 | GCr15 |

52100 Chemical Composition

| C | Si | Mn | P | S | Cr | Ni | Cu |

| 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | ≤0.025 | ≤0.025 | 1.4-1.6 | ≤0.25 | ≤0.25 |

Mechanical Properties of ASTM A295 52100 Bearing Steel

| Properties | Metric | Imperial |

| Bulk modulus (typical for steel) | 140 GPa | 20300 ksi |

| Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Hardness, Brinell | – | – |

| Hardness, Knoop (converted from Rockwell C hardness) | 875 | 875 |

| Hardness, Rockwell C (quenched in oil from 150°C tempered) | 62 | 62 |

| Hardness, Rockwell C (quenched in water from 150°C tempered) | 64 | 64 |

| Hardness, Rockwell C (quenched in oil) | 64 | 64 |

| Hardness, Rockwell C (quenched in water) | 66 | 66 |

| Hardness, Vickers (converted from Rockwell C hardness) | 848 | 848 |

| Machinability (spheroidized annealed and cold drawn. Based on 100 machinability for AISI 1212 steel) | 40 | 40 |

Alloy Steel 52100 Steel Ball Supplier

JHSTEESTEELBALLS provides customized made AISI 52100 steel balls for car CV joints and other rolling joints in market. If you are looking for car CV joint balls or chrome steel balls feel free to contact us for the latest price.

Material:

AISI 52100/ 100Cr6/ 100C6/ SUJ2/ Wks 1.3505/ GCr15.

Size:

From 10mm to 30mm

Package:

Plastic Bag + Cardboard Box + Wooden

Supply Ability:

300T/Month

Lead Time:

30 Days

Contact JHSTEELBALLS

Contact JHSTEELBALLS to get high quality and precision steel balls for your applications, bearings lines and any other applicable places. We will reply within 24 hours

- Address: Jinghua Industrial Park, Lilou Town, Luolong District, Luoyang, Henan Province, China

- Email: sales@jhsteelballs.com

- Phone: +86 139399292454566